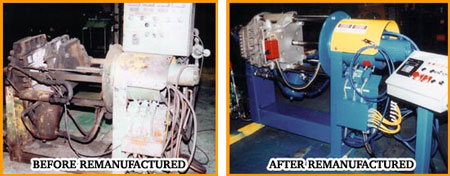

Remanufactured Core Machinery

FAR Products, Inc. remanufacturing services give your old core machine a new lease on life. Save on ongoing maintenance costs and unscheduled down time. Save money by having a virtual new machine with the latest controls versus purchasing new.

A STANDARD REMANUFACTURING PROGRAM

All machines receive:

- Water blast cleaning of unit and any accessories

- Disassemble and remove all items and controls to bare frame

- Clean and inspect all components

- Repair and replace all items not serviceable

- Regrind mounting surfaces flat

- Sandblast main weld joints and castings

- Install new shafting

- Reassemble machine using new bushings, bearings, and seals

- Plumb the unit with new hose

- Plumb and repair the gas burner system

- Rewire all machine mounted electrics

- Paint unit complete

- Run, test, and adjust machine

- Load out unit for shipment to your location

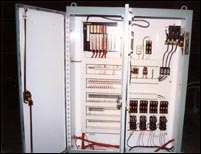

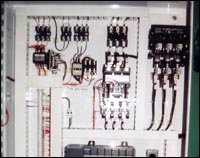

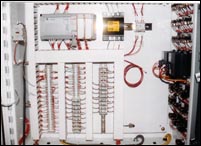

STATE OF THE ART CONTROLS

All machines are supplied with a new control panel and PLC control. Panel includes:

- New NEMA enclosure

- Fused flanged disconnect on U-180 only

- Allen Bradley components throughout

- AB Micro logic PLC controller with EPROM memory chip and fused outputs

- Indicating fuses

- Internal transformer for 460 3ph to 110 vac control circuitry on U-180

- New 35mm Allen Bradley control buttons

- Allen Bradley DTAM access source for timing and fault warnings

- Ladder logic printout, hard wiring diagram, and the PLC program

- Unit wiring and testing

- Updated copy of the operations and part list manual